The ideal material for sustainable yacht manufacturing

Aluminum Mastery:

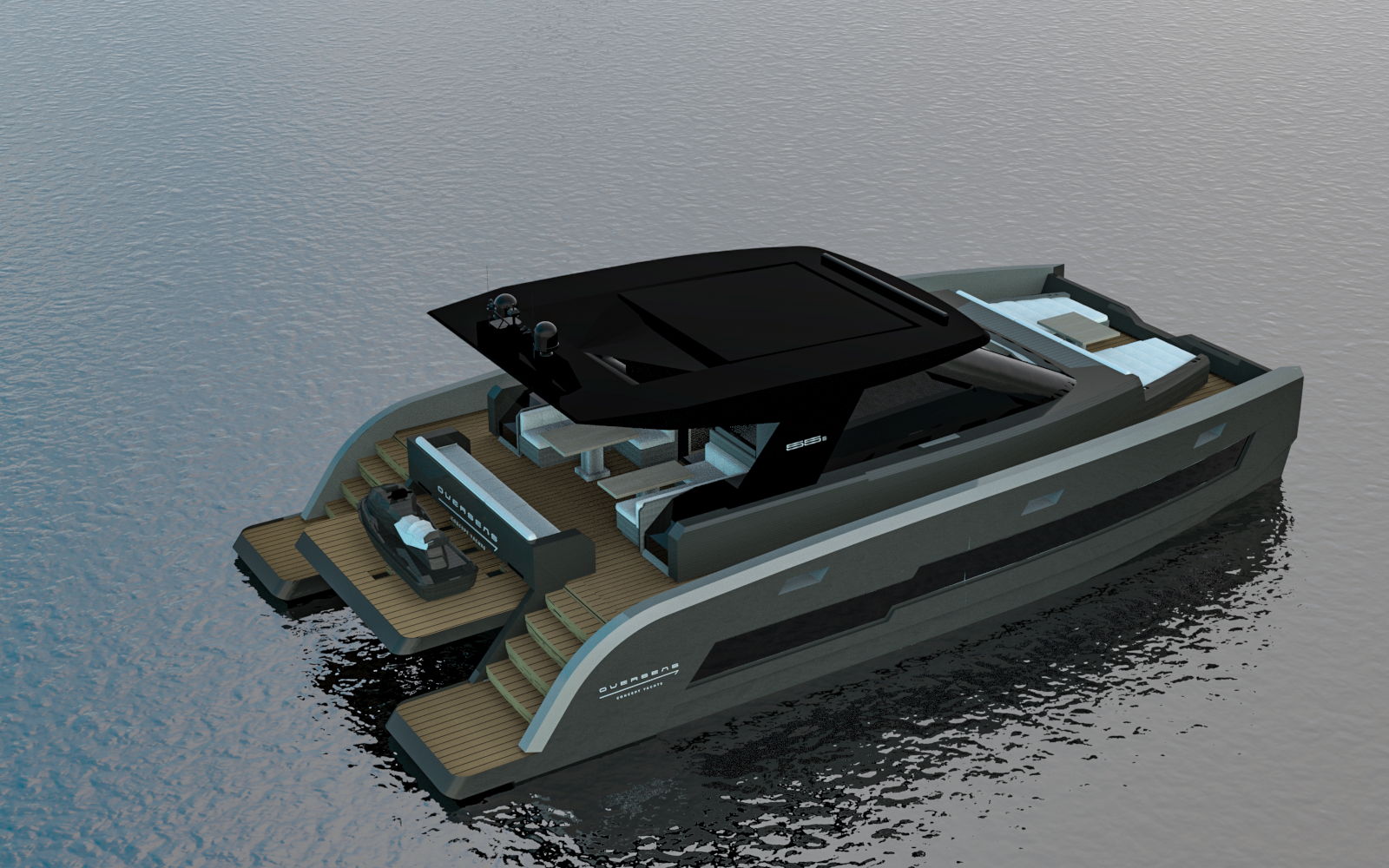

Empowering the Future with Precision-Engineered Catamarans Aluminum, a versatile and lightweight element, stands at the helm of modern catamaran engineering. Its exceptional strength-to-weight ratio enables precision in crafting sleek, high-performance vessels. With corrosion resistance against the sea's elements, aluminum ensures enduring durability, propelling catamarans to navigate waters with agility and efficiency.

Sail Beyond:

Catamarans epitomize innovation in maritime design, embodying elegance, stability, and speed. Their dual-hull configuration harnesses stability while maximizing space and comfort. From leisurely cruises to competitive racing, catamarans carve through waves, offering an unparalleled experience of grace and adventure on the water.

Recycling requires only 5% of the energy needed for new production.

Unique Strengths

01.

Enhanced

speed

Power Catamarans notably offer faster speeds compared to Sailing Catamarans.

02.

Cruising

at Low Costs

Sailing Catamarans reach speeds of 8-10 knots, while Power Catamarans can achieve 14-15 knots. Remarkably, the Overseas 55 ΗΤ attains a cruise speed of up to 30 knots with significaly lower fuel consumption due to its lightweight aluminum construction.

03.

Durability

Crafted entirely from marine-grade aluminum 5 series (AI-Mg), renowned for its premium attributes - durability, lightweight composition, safety, adaptability, and recyclability.

Empowering the Future

Aluminum is valued for its lightweight, rigid, and durable nature, making it an excellent material choice known for requiring minimal maintenance and offering long-lasting performance.

Aluminum is highly light, rigid, and sturdy.

It also doesn’t need to be maintained constantly. Additionally, aluminum is a superb material because it has the greatest fire safety rating (category A1 according to European laws) of any material.

Aluminum is one of the few metals that is both readily available and recyclable.

In fact, because of its recycling capabilities, up to 75% of all aluminum ever produced is still in use. Only 5% of the energy needed to generate the same amount of new aluminum is needed to melt used metal.

Stability

The IEA reports that the direct CO2 intensity of aluminum production has been stable during the last few years, and in their Net Zero Emissions by 2050 Scenario, they predict that the intensity of emissions will decrease by 3% per year by 2030. In other words, as recycling techniques improve, the amount of energy and resources needed to produce aluminum will continue to decline.

Adaptability

Because of its adaptability, additional metals can be added to aluminum to strengthen some of its inherent features, such as sturdiness and waterproofness. Aluminum is not always utilized as a 100% pure material. Aluminum is an alloy that delivers a level of performance comparable to titanium and sophisticated steels. Additionally, aluminum is a substance that is widely used, which increases its durability.

Aluminum attributes

These attributes collectively position aluminum as an ideal material for yatchts manufacturing, boasting both sustainability and recyclability. Aluminum vessels can be completely recycled at the conclusion of their exceptionally long life-spans with minimal energy consumption. While the recognition of aluminum's potential in various industries is relatively recent, Overseas Concept Yachts has long acknowledged its advantages, establishing ourselves as industry pioneers in leveraging aluminum for power catamaran production.

Aluminum attributes

-

Lightweight, rigidity, and durabilityAluminum is prized for its remarkable lightweight, rigidity, and durability, making it an exceptional material choice. Its inherent strength requires minimal maintenance, offering convenience and long-lasting performance.

-

Superior fire safety ratingFurthermore, aluminum stands out as an excellent material choice due to its superior fire safety rating, classified as category A1 according to European regulations, surpassing that of any other material.

-

Aluminum remains in circulationIn fact, owing to its recyclability, approximately 75% of all aluminum ever manufactured remains in circulation. Moreover, merely 5% of the energy required to produce an equivalent quantity of new aluminum is necessary to melt recycled metal.

-

CO2 intensity of aluminum productionAccording to the International Energy Agency (IEA), the direct CO2 intensity of aluminum production has remained steady in recent years. However, in their Net Zero Emissions by 2050 Scenario, they anticipate a 3% annual decrease in emissions intensity by 2030. This projection suggests that as recycling methods advance, the energy and resources required for aluminum production will continue to diminish.